[VR6] Fuel, suspension and all around

So my life goes in garage where I continuously keep designing things. Or in others words dealing with circumstances in case something does not fit, which to be honest is almost a constant.

It happens so because everything I fit in this car it actually have not been there and probably shouldn't but then again.. hold my beer...

In this part, I'll do an attempt on what I've had achieved so far:

- half axles renewed partially;

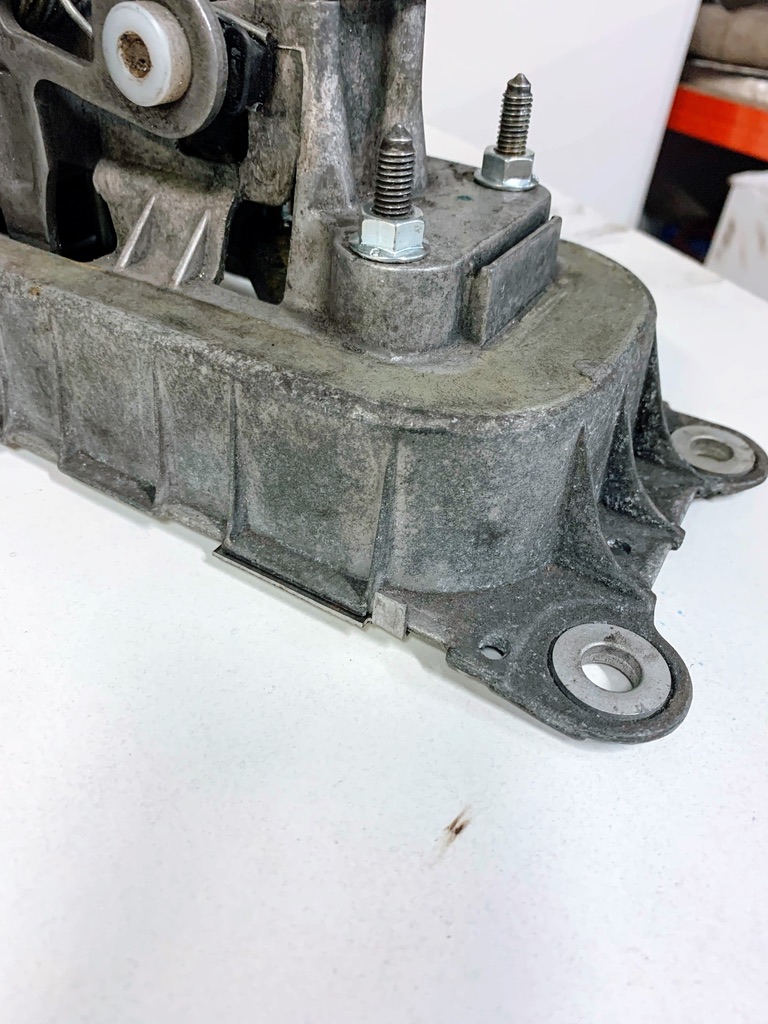

- 02M cable shifter tower box adapted;

- addition of Dieselgeek short shifter mechanism;

- head lights renewal;

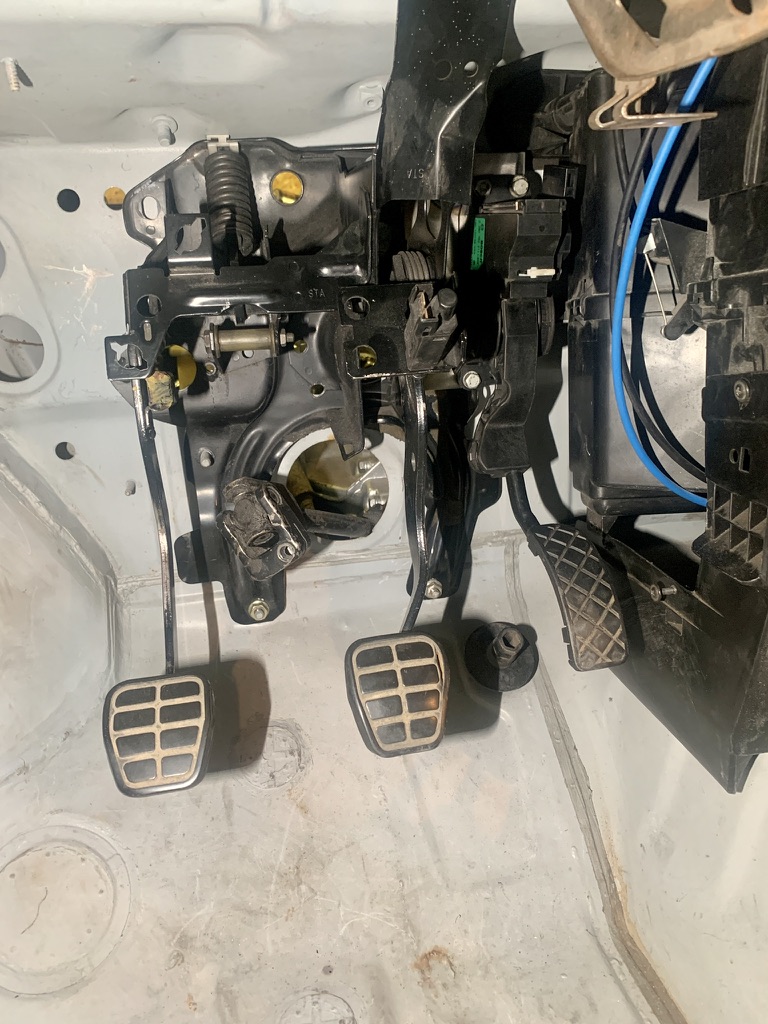

- Bosch DBW and Bosch DBW pedal assembly;

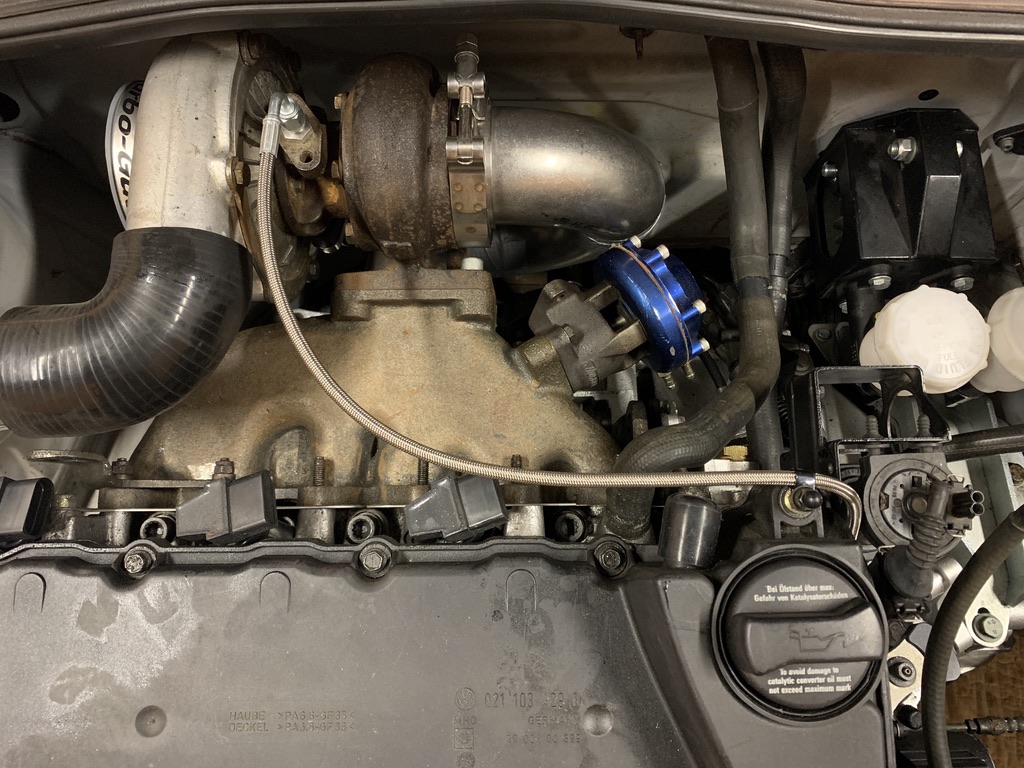

- turbocharger oil feed AN4;

- turbocharger oil drain AN10;

- fuel catch tank accommodation;

- assembly of fuel lines;

- IAT installation;

- renewal of FRONT OE 288mm brake system;

- renewal of REAR Syncro brake disc system;

- engine lift hoop;

- various bracket there and there.

To begin with, let's go to smaller bits like half axles. These front pieces came from mk4 2.8 VR6 Golf, passenger side was shortened slightly because it wouldn't fit.

That's old and good condition OE units. Just lubed freshly and sealed decently. Nothing major.

Later I moved to bit different place to challenge myself while fitting cable shifter box. Initial point looked like this where I wanted identify how all things combined will look like.

As you can see there are plates visible under shifter tower which I fabricated as I intended to weld them on a tunnel.

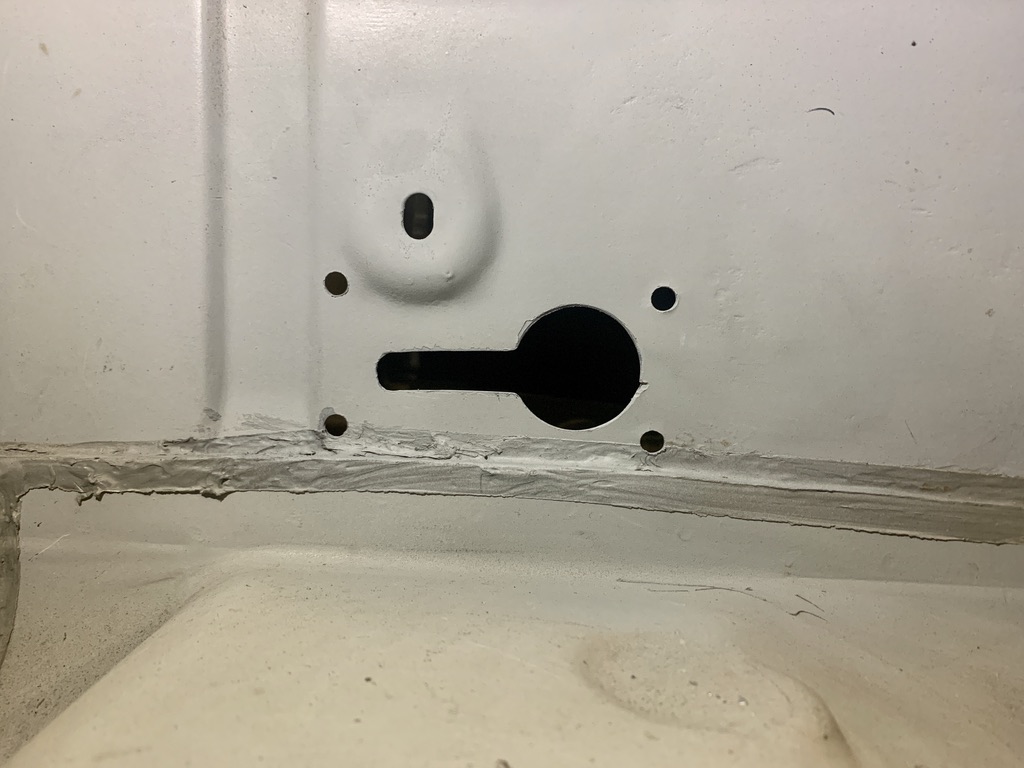

Next it was cables itself and how to get them through firewall decently. I didn't want just a hole they get through to be a very big so this awkward shaped hole was punched.

But it's quite neat once grommet and cables fitted altogether

tadaaam

I'm huge fan of Dieselgeek products so have fitted it to replace massive OE on gearbox tower with this neat setup.

I did not have front headlights in good shape so got it through renewal process. Bracket and other metals parts were put together with perfect condition glass.

Looks now sufficiently well

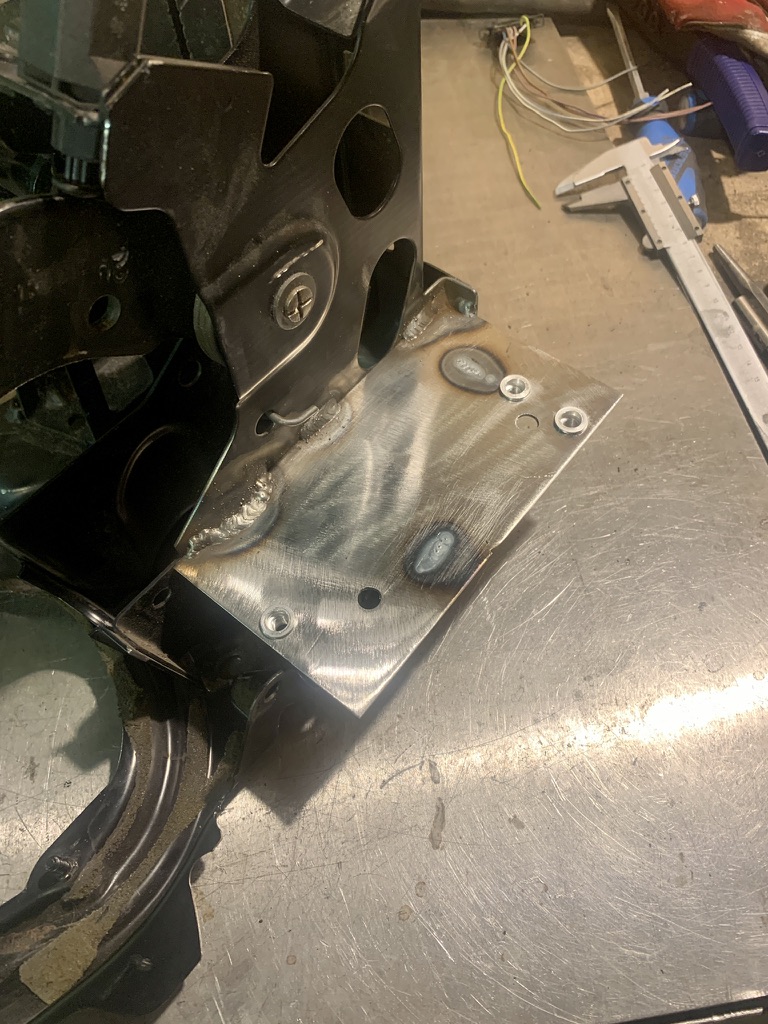

Brackets and brackets, brackets everywhere:

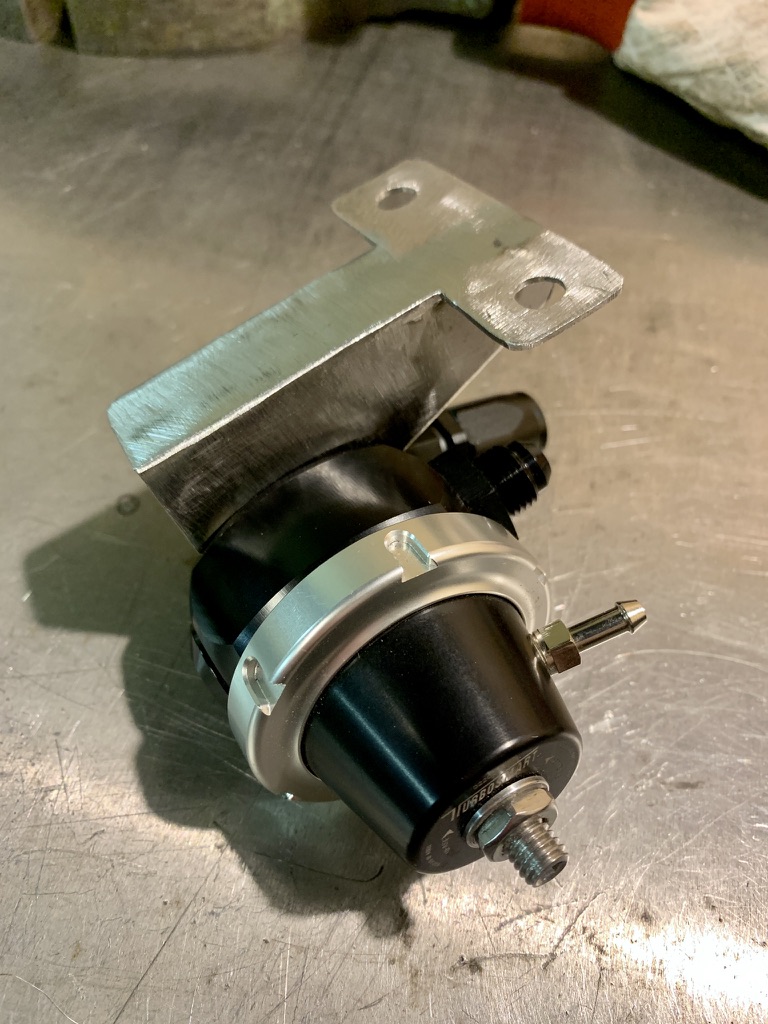

Fuel pressure regulator bracket:

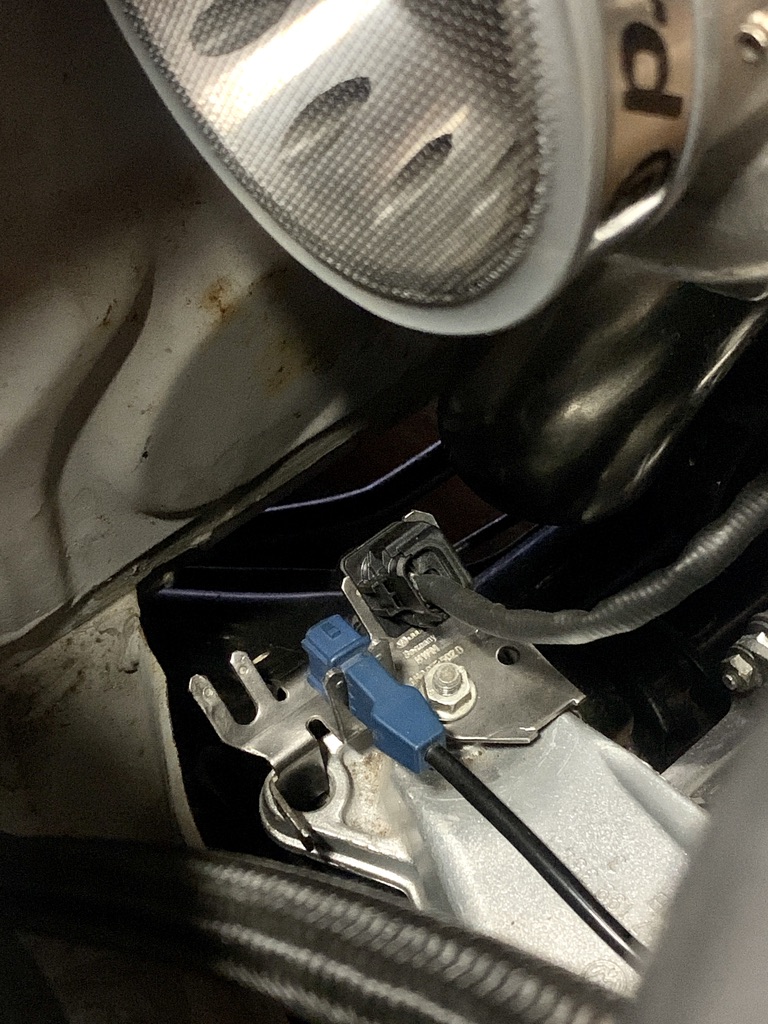

I've also planned to run DBW (drive by wire) instead of cable controlled throttle body.

To achieve this you need DBW fitted on intake manifold which actually is in place already, meanwhile another part of it was not solved. So let's do like this:

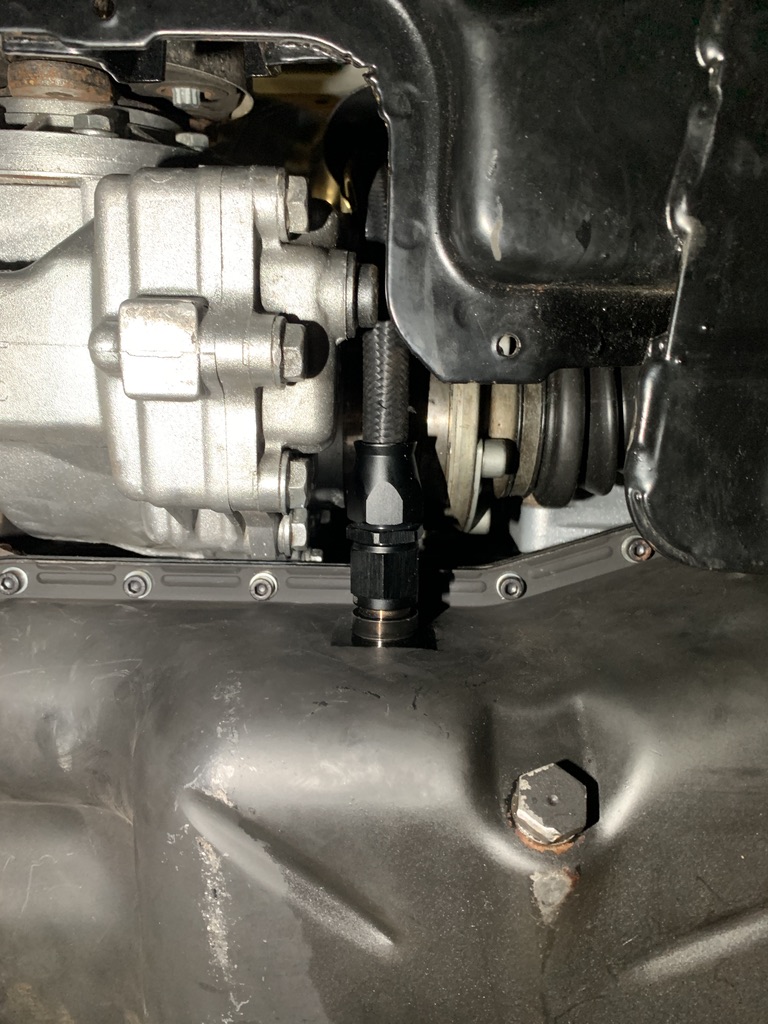

I had an intention to connect turbo oil feed and drain. For a starter let's get to drainage first. Sourced required AN10 fittings and some of PTFE hose to connect everything

Straight one AN10 and turbo side flange

I'm going to use old 12v oil pan which for sure had no bung on it - so it's inevitable:

With hose of course secured in place by using nylon P clips:

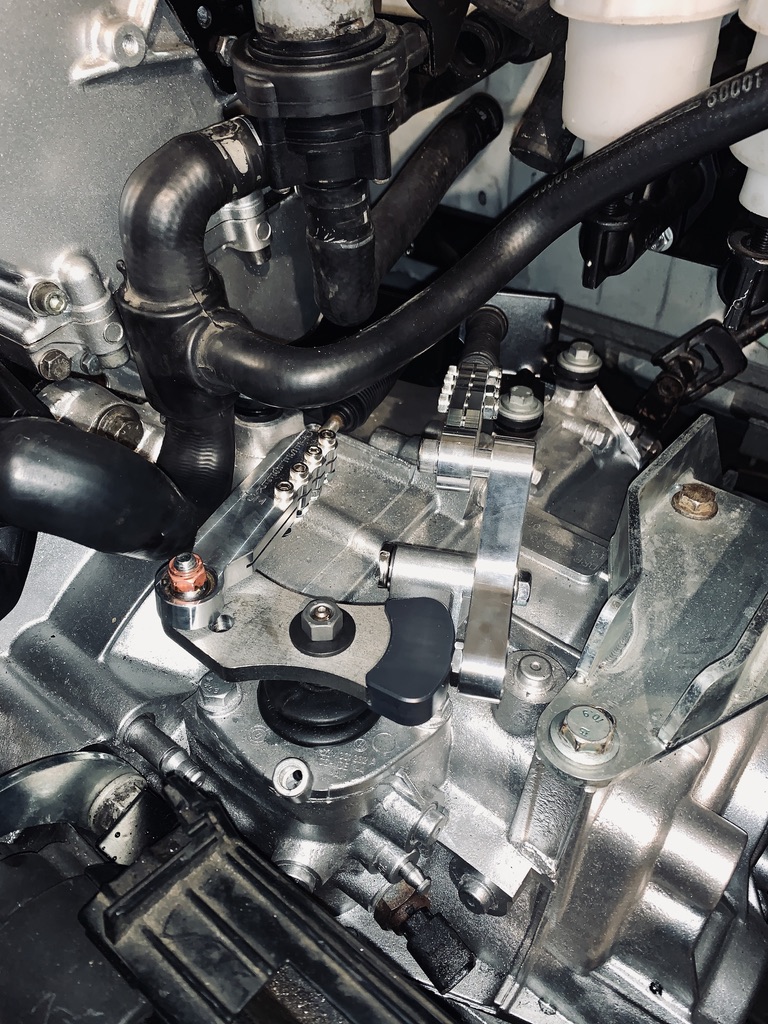

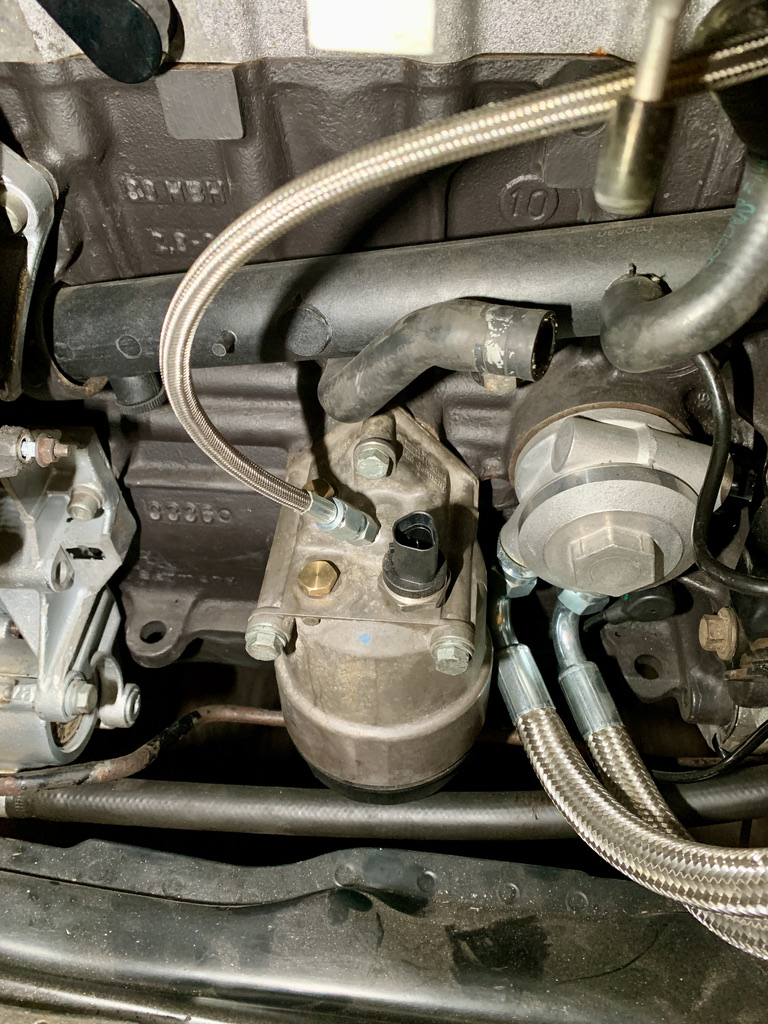

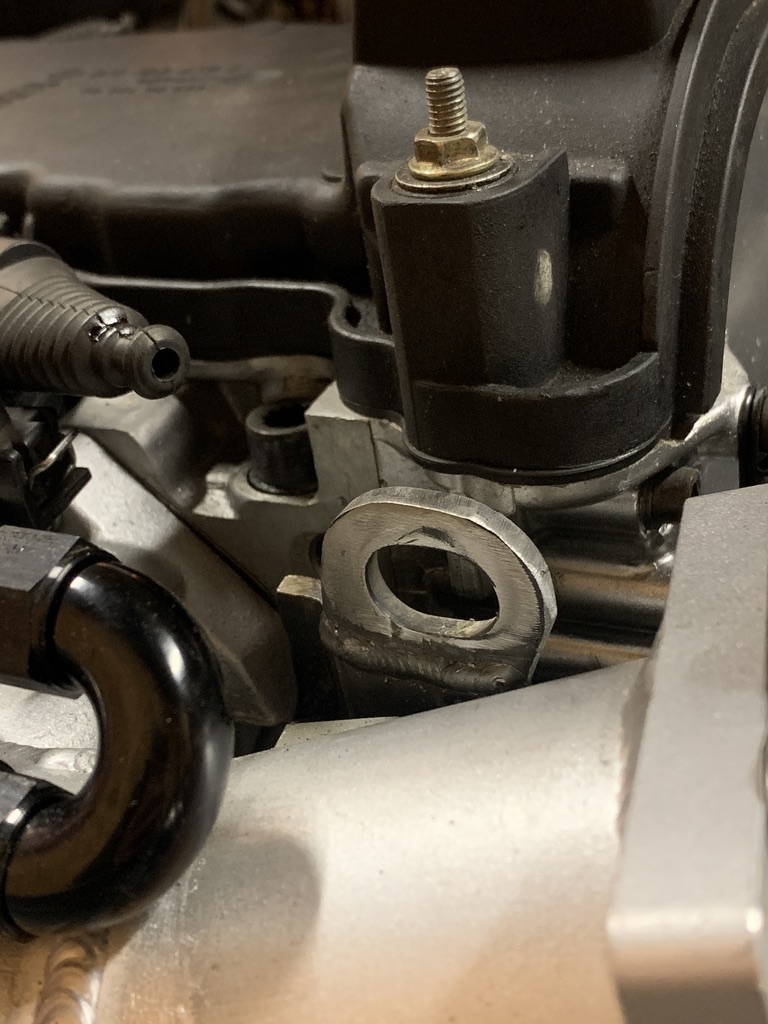

For turbocharger oil feed to work properly I was advised to use only clean filtered oil supply, therefore I start here:

Tapped a thread and used adapter from M10x1 male to AN4 to connect feed line. Simple.

Something to add I did get rid of OE low oil pressure and temperature sensors and went compound Bosch sensor way (temp+pressure in single unit). Other outputs became unnecessary so blanked them with brass blanks:

That's how it reached turbocharger:

I brought OE brake setup, have it renewed slightly and made it ready to be fitted:

Back to engine, had put in place an ordinary IAT. I know my TIG welding skills are not up to my desire at the same time can't deny it wouldn't work:

After I swapped inlet manifolds it appears I was not able to attach an engine it's lift hoop back. I was forced to change it's orientation by 90 degrees from this:

To this:

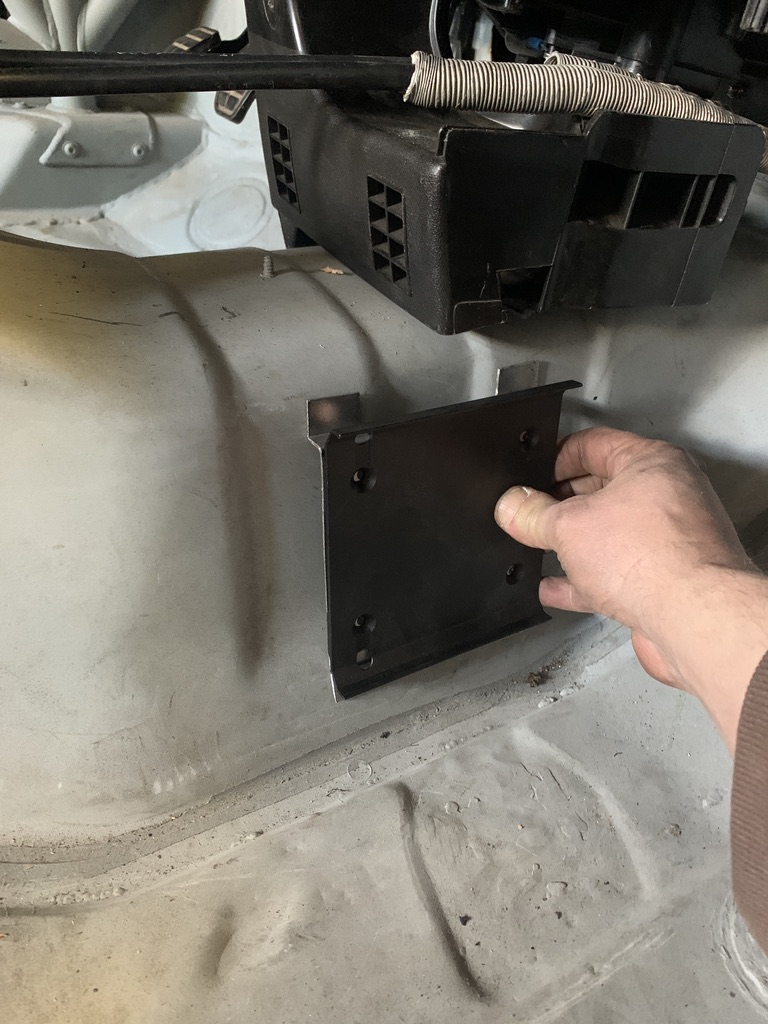

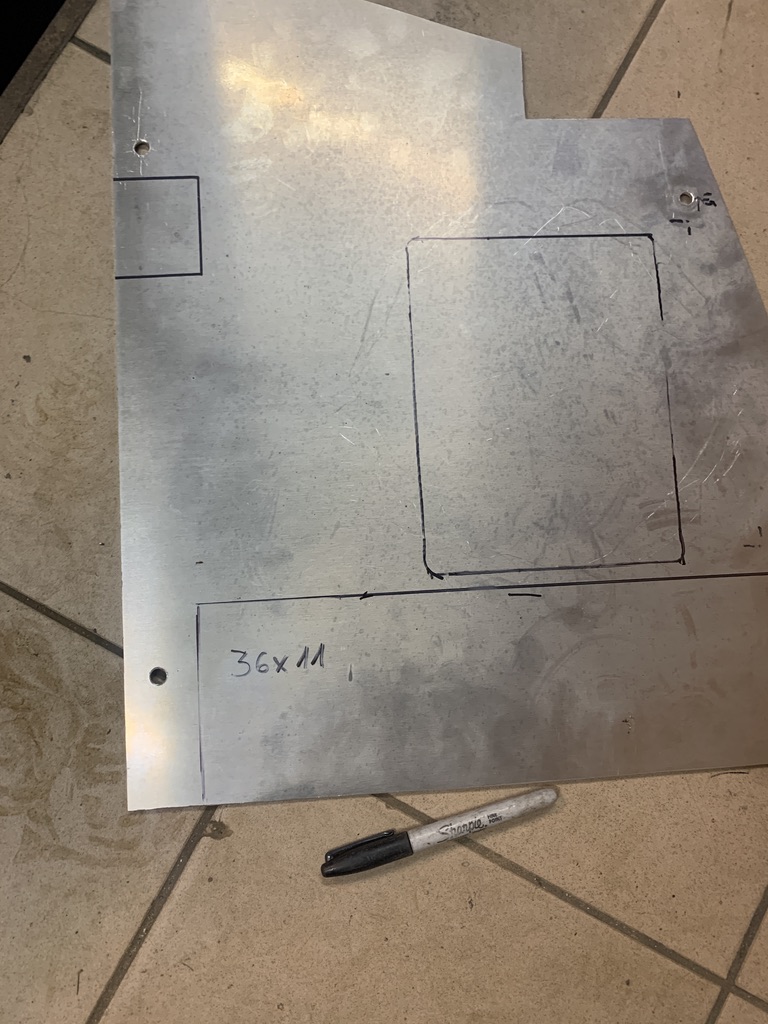

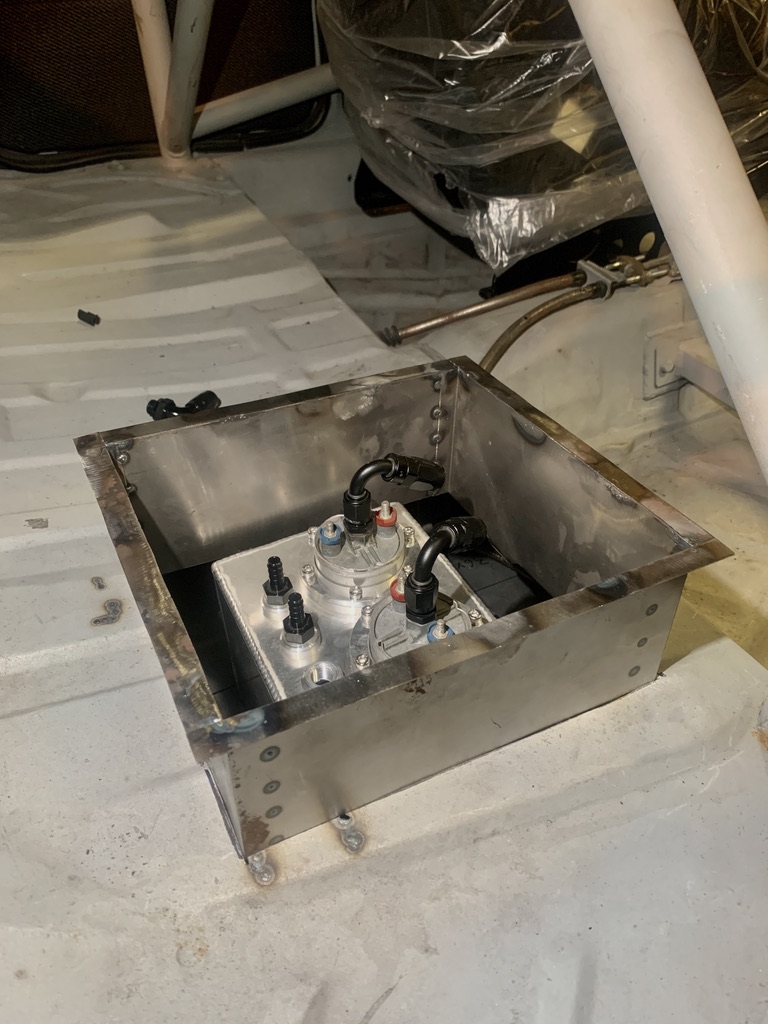

For the end I'll leave part which required significantly more effort compared to other bits - that is fuel supply line building. I had in my plans to twin Bosch 044 fuel pumps (master and slave) for a couple of reasons I won't discuss here. Also I was tempted to add fuel cooler near it. While seeking to fit somehow nicely avoiding shell ruining - it started to become challenging. Orientation, positioning, dimension, space limitations at the planning phase did not play together and nicely in my mind, nor it did on paper. After long time spent on thinking I've started first actions. That's where all of it will land I decided:

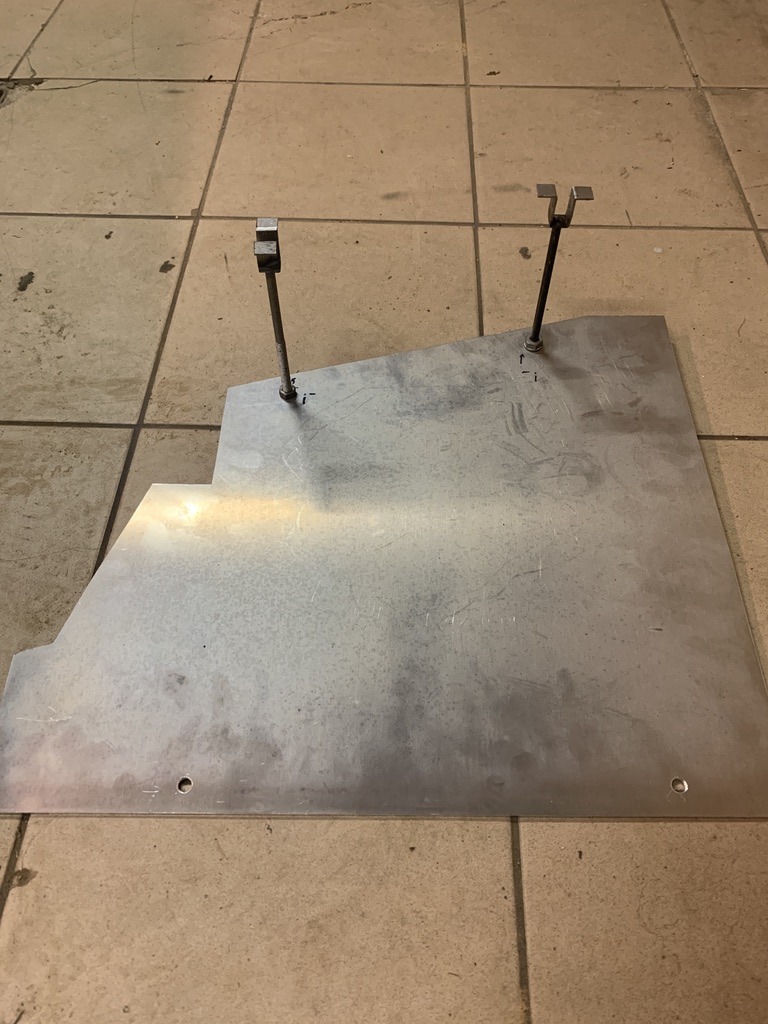

Floor for fuel catch tank and all that stuff related:

Finally some tangible result:

Fuel pump trial fit:

Bolted on:

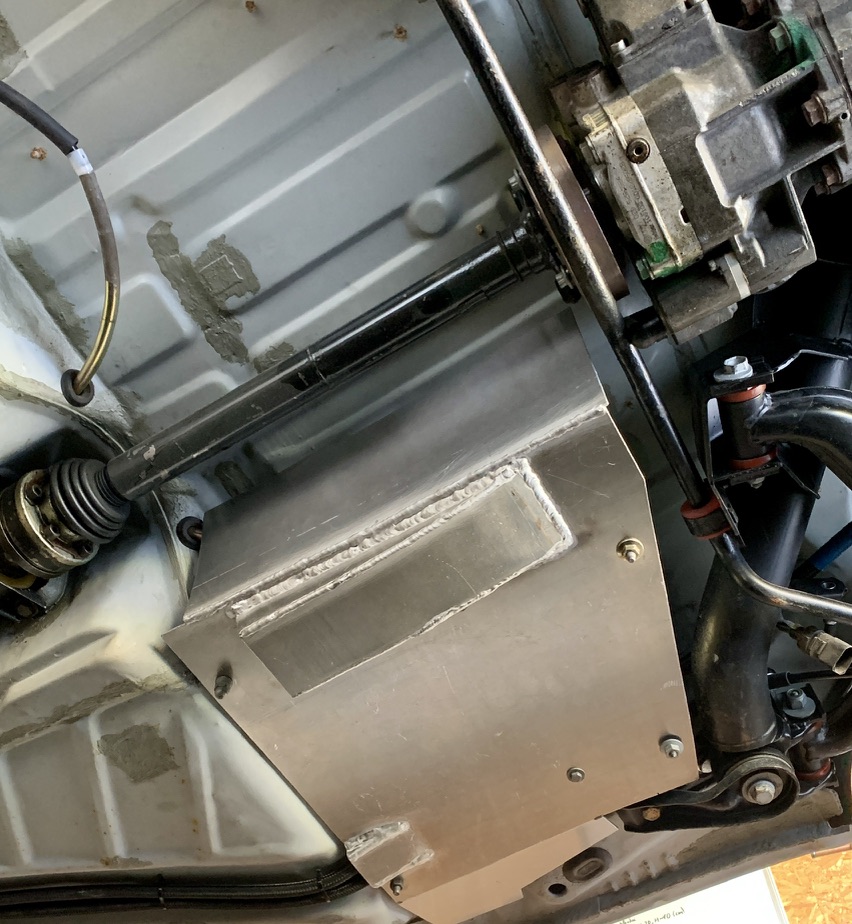

Needed to close everything so later I could seal it completely from interior:

Looks like a house building:

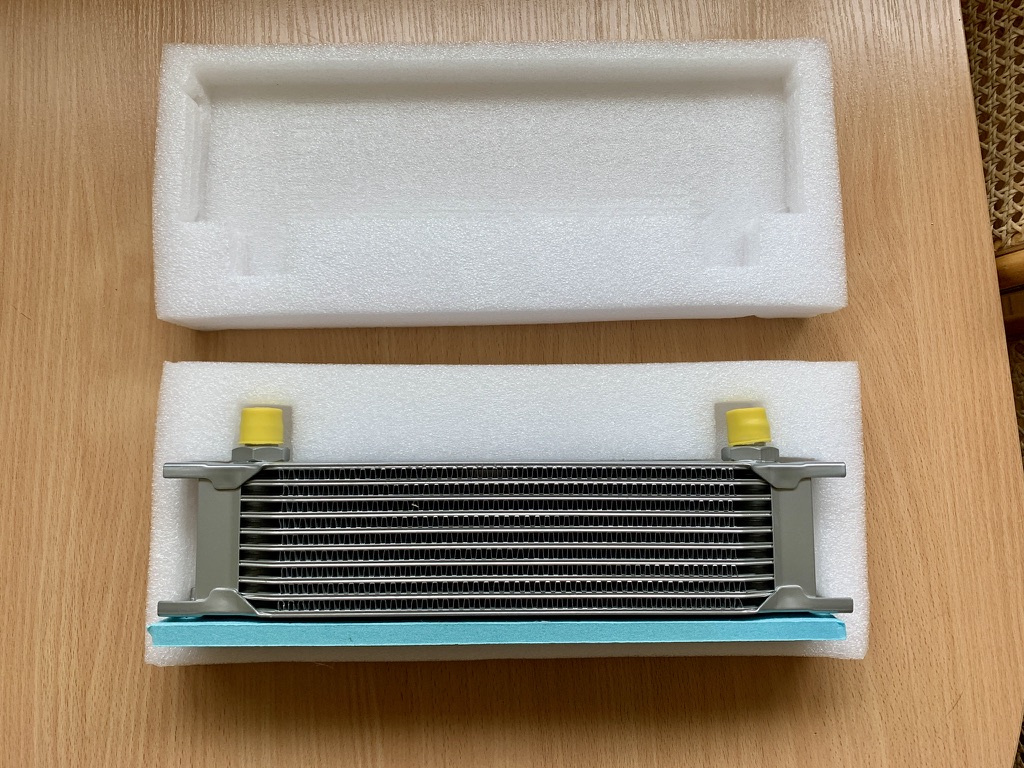

Now it's time to get back to floor itself where reservoir stands on. And next to it fuel cooler radiator will be hosted:

Some minor isolation away from propeller shaft. I still need to spend purposeful time on practicing TIG welding because I lack consistency as you can see:

Could be better but that's how we gonna roll this time:

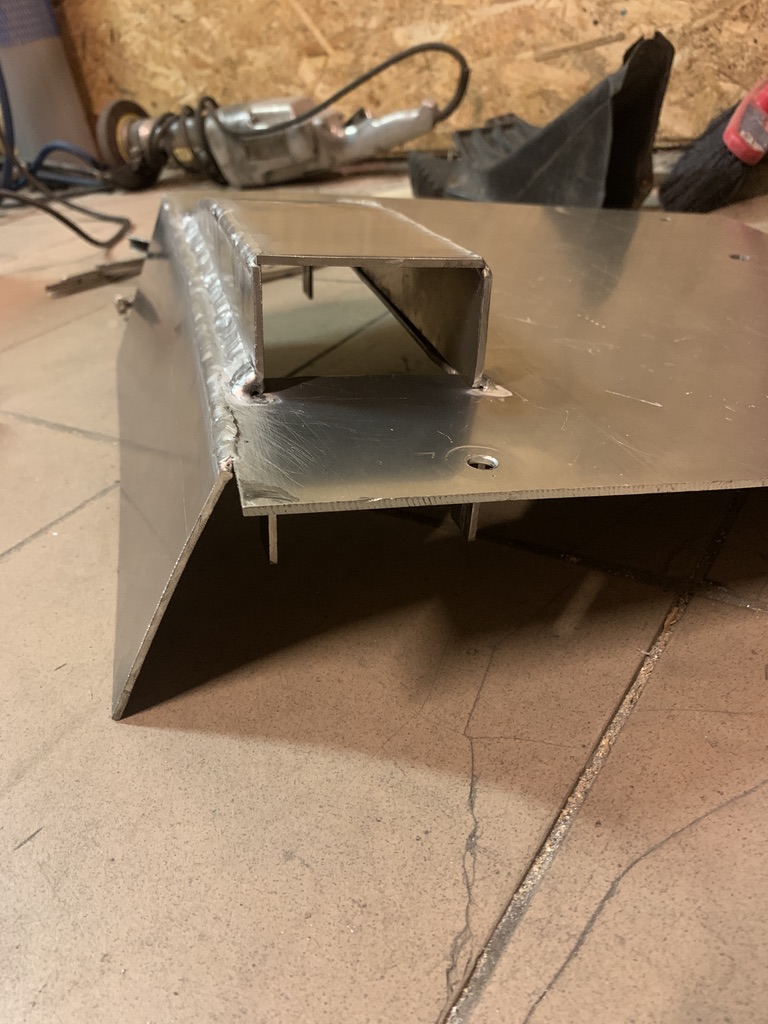

Building some primitive scoop underneath:

Under car view would be like:

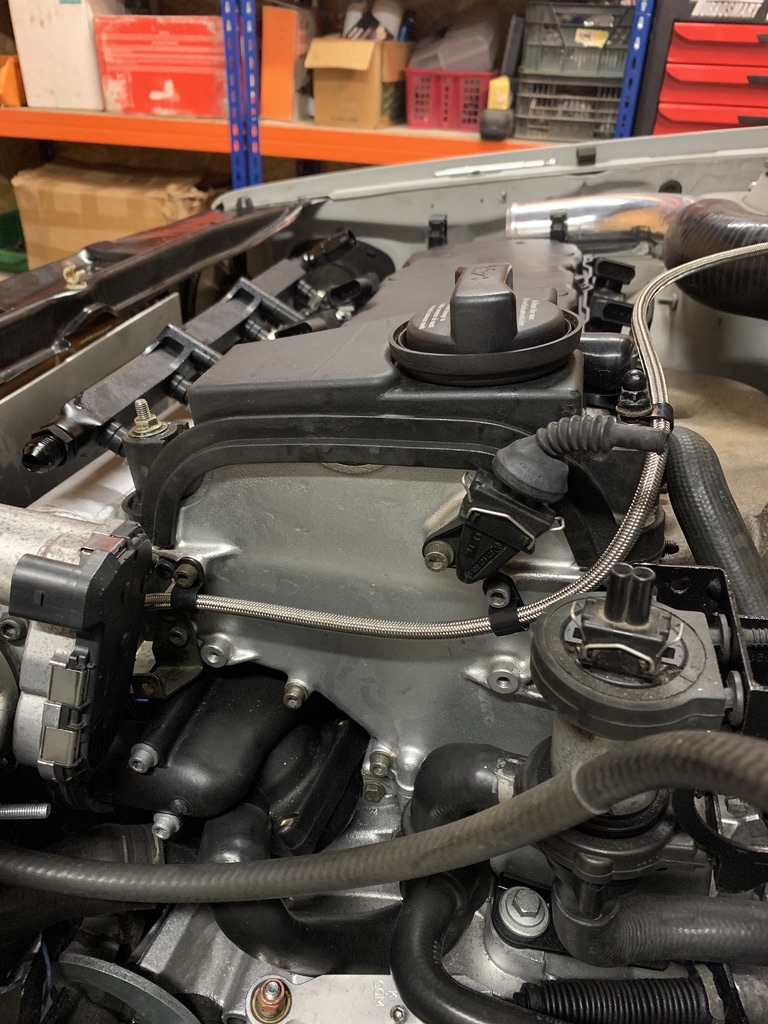

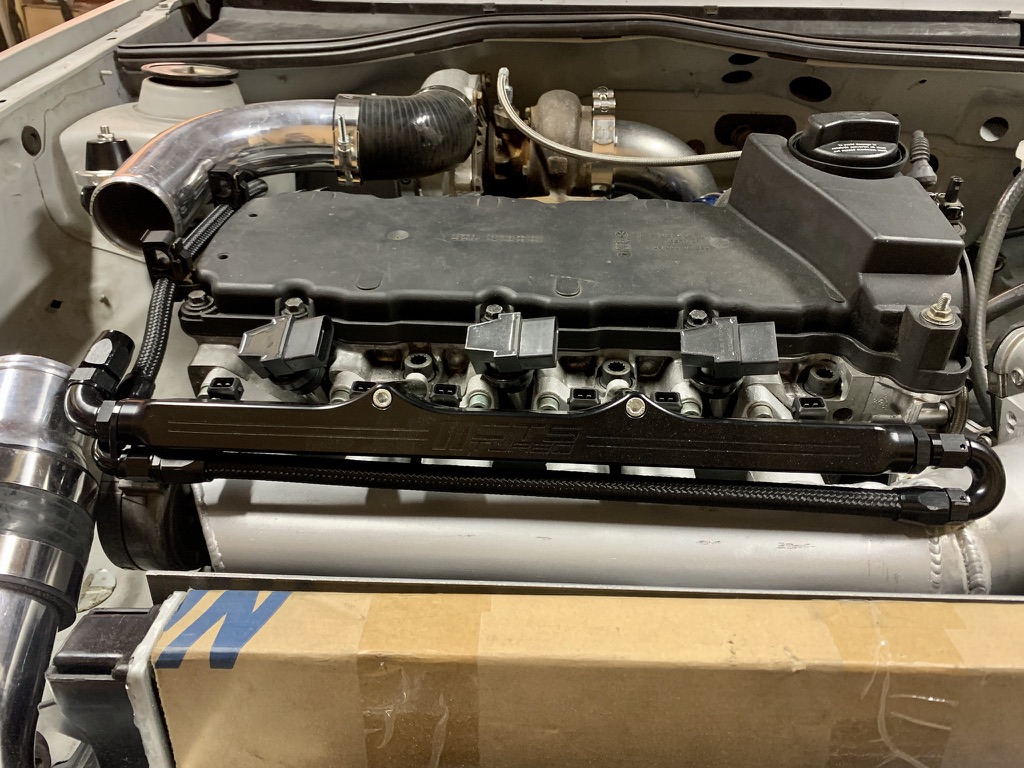

Fuel line from rail to catch tank was assembled too. Starting from CTS AN8 fuel rail combined with Bosch 6x 1200cc injectors:

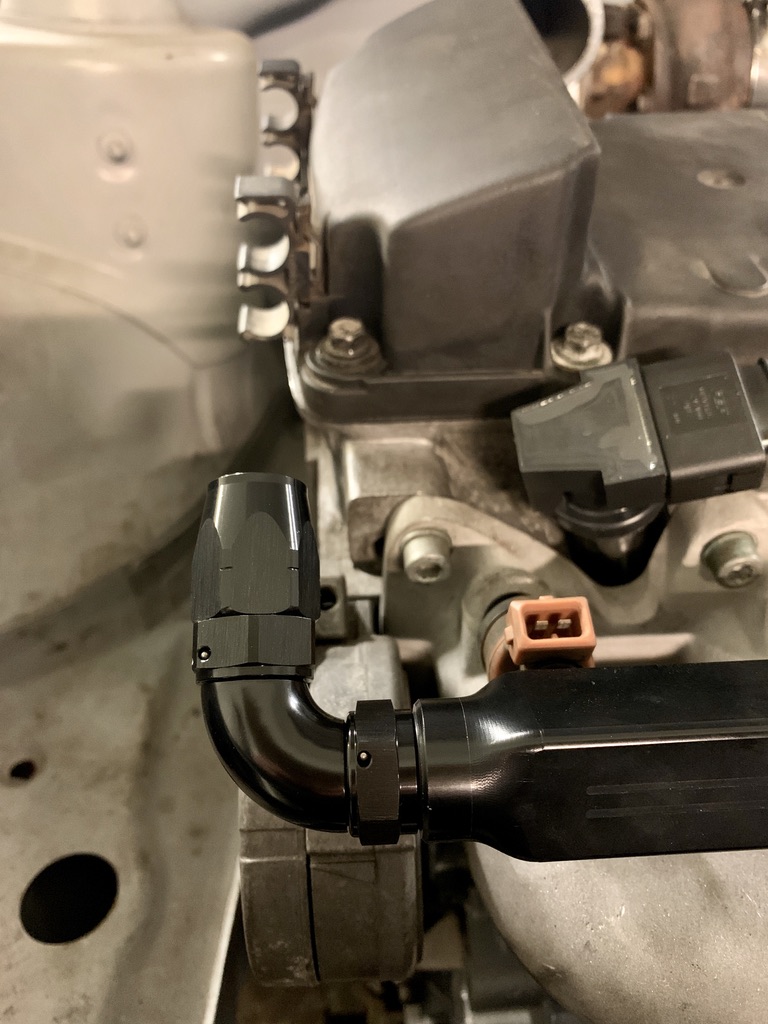

AN stuff, AN stuff, give some more:

Return line AN6:

More or less it's completed:

As usually there are more material I could present. This time I'll stop here and keep working on car. Once it will get significant amount of items aggregated I could present so I will do.

For now stay healthy!

Hits: 4946